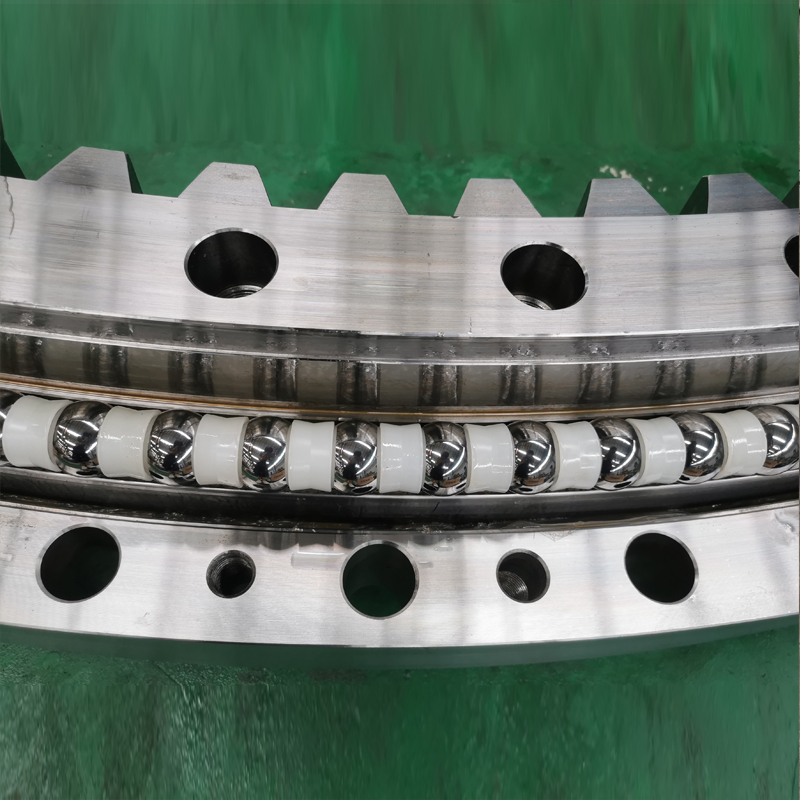

Ball Slewing Ring

- Ball slewing rings are versatile bearings designed to handle axial, radial, and overturning moment loads simultaneously.

- Their compact and lightweight structure makes them ideal for applications requiring efficient space utilization and flexible rotation.

- Widely used in construction machinery, wind turbines, and material handling systems, they ensure reliable performance under diverse conditions.

Product Description:

The ball slewing ring is a specialized bearing designed to handle combined loads, including axial, radial, and overturning moment forces. It uses rolling balls as its primary rolling elements, providing smooth rotation and flexibility while maintaining a compact structure. Ball slewing rings are widely used in various industrial applications, such as construction machinery, wind turbines, and material handling systems, where efficient rotation and load-bearing are critical.

Features:

● High Load-Bearing Capacity

Ball slewing rings are designed to handle multi-directional loads, including axial and radial forces, as well as overturning moments. This makes them suitable for diverse working conditions.

● Compact and Lightweight Design

Their compact structure and lightweight design enable efficient space utilization, making them ideal for applications with tight space constraints.

● Diverse Structural Options

Available in single-row four-point contact, double-row ball, and three-row roller configurations, they cater to various load and performance requirements. Single-row designs are ideal for moderate loads, while double-row and three-row configurations handle higher loads and demanding conditions.

● Smooth and Precise Rotation

Precision-engineered raceways and rolling elements ensure low friction and smooth rotation. This minimizes wear and reduces noise, providing consistent and reliable performance.

● Excellent Sealing Performance

Equipped with high-quality sealing systems, ball slewing rings effectively prevent contaminants such as dust, water, and debris from entering the bearing, ensuring long-term operation even in harsh environments.

Applications:

● Construction Machinery

Commonly used in excavators, cranes, and rotary drilling rigs to support and facilitate the rotation of upper structures.

● Wind Energy

Ball slewing rings are employed in wind turbines for yaw and blade pitch control, where precision and durability are crucial.

● Port and Material Handling Equipment

Widely used in port cranes, stackers, and reclaimers for efficient rotation and load-bearing in heavy-duty operations.

● Industrial Automation

Used in robotics, machine tools, and rotary tables for precise and reliable rotational motion.

● Military and Aerospace

Ball slewing rings are integral to radar systems, missile launchers, and other rotary applications requiring stability and precision.

Maintenance and Care:

● Regular Lubrication

Periodically apply appropriate grease to reduce friction and wear, ensuring optimal performance and extended service life.

● Inspect Seals

Check and replace damaged seals promptly to prevent contamination and maintain bearing integrity.

Operate within the specified load limits to prevent premature wear or failure.

● Wear Monitoring

Regularly inspect the bearing for signs of wear, ensuring timely maintenance or replacement if necessary.

With their exceptional load-handling capabilities, compact design, and smooth rotation, ball slewing rings are essential components in modern machinery. Their versatility and reliability make them the preferred choice for industries requiring precise and efficient rotary motion.

THANK YOU FOR YOUR ATTENTION HUAXIN!

If you are interested in this steel product, please fill in this form, we will reply you as soon as possible.

.jpg)

.jpg)