Precision Turntable Bearing

10 Years Of Manufacturing, R&D And Sale

- Characteristic of structure: Three row roller slewing bearing is composed of two seat rings

- Performance: Can withstand axial force, radial force and overturning moment

- Features: Used in rotary conveyors, welding operators, light and medium-sized cranes, excavators and other construction machinery

Precision turntable bearing, also known as precision slewing rings or precision rotary table bearings, are designed for applications requiring high accuracy, smooth rotation, and the ability to handle combined axial, radial, and moment loads. These bearings are widely used in machinery that demands precise positioning and reliable performance, such as robotics, medical equipment, radar systems, and precision engineering tools.

Key Features Precision Turntable Bearing:

- High Precision: Engineered to provide extremely accurate rotational movement, ensuring minimal deviation and high reliability in precision applications.

- Smooth Operation: Designed with high-quality materials and precise manufacturing processes to deliver smooth and consistent rotation.

- Load Handling: Capable of supporting substantial axial, radial, and tilting moment loads, making them suitable for complex and demanding applications.

- Durable Construction: Made from premium materials such as hardened steel or stainless steel, with surface treatments to enhance wear resistance and longevity.

- Low Friction: Features optimized internal geometries and high-quality rolling elements to minimize friction and ensure efficient operation.

- Compact Design: Offers a compact and lightweight design without compromising load capacity or performance, making them ideal for applications with space constraints.

- Sealing Options: Equipped with effective sealing solutions to protect against contaminants such as dust, dirt, and moisture, ensuring long-term reliability.

- Customization: Available in various sizes and configurations, and can be customized to meet specific application requirements.

Applications:

- Robotics: Used in robotic arms and automation systems for precise positioning and reliable rotation.

- Medical Equipment: Essential in medical imaging devices, surgical robots, and other precision medical instruments for smooth and accurate movement.

- Radar Systems: Employed in radar and communication systems for stable and precise rotational functionality.

- Precision Engineering: Used in CNC machines, rotary tables, and other precision engineering tools for high-accuracy operations.

- Aerospace: Utilized in satellite positioning systems, antennas, and other aerospace applications requiring high precision and reliability.

Technical Specifications:

- Load Capacity: Varies depending on the model and size, typically designed to handle a range of loads from light to heavy-duty.

- Bearing Type: Available in single-row and double-row ball bearings, cross-roller bearings, and other precision configurations.

- Material: Generally made from high-grade hardened steel or stainless steel, with optional surface treatments for enhanced durability.

- Diameter: Customizable to fit specific machinery dimensions, with diameters ranging from small sizes for compact applications to larger sizes for heavy-duty use.

- Sealing: Options include single and double seals to protect against environmental factors.

- Friction Coefficient: Designed to maintain a low friction coefficient for efficient and smooth operation.

Maintenance and Care: To ensure optimal performance and longevity, regular maintenance is essential. This includes periodic lubrication, inspection for wear and damage, and replacement of seals as needed. Proper installation and alignment are also crucial to prevent premature failure and ensure efficient operation.

Conclusion: Precision turntable bearing is essential components in many high-accuracy and demanding applications, providing reliable and precise rotational movement. Their high precision, smooth operation, and robust construction make them suitable for a wide range of industries, including robotics, medical equipment, radar systems, precision engineering, and aerospace. With customizable features and effective sealing solutions, these bearings offer versatile and long-lasting performance in challenging environments.

Also check our new product by clicking here.

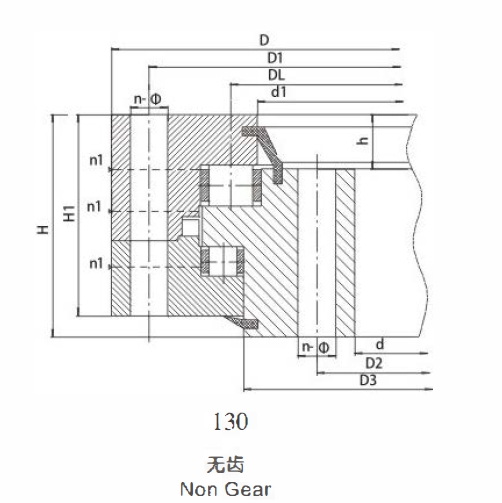

| No. | Non gearDLmm | Dimensions | Mounting Dimensions | Structural Dimensions | |||||||||||

| Dmm | dmm | Hmm | D1mm | D2mm | n | φmm | dmmm | Lmm | nlmm | HImm | hmm | Weig kg | |||

| 1 | 130.25.500 | 634 | 366 | 148 | 598 | 402 | 24 | 18 | M16 | 32 | 4 | 10 | 32 | 224 | |

| 2 | 130.25.560 | 694 | 426 | 148 | 658 | 462 | 24 | 18 | M16 | 32 | 4 | 10 | 32 | 240 | |

| 3 | 130.25.630 | 764 | 496 | 148 | 728 | 532 | 28 | 18 | M16 | 32 | 4 | 10 | 32 | 270 | |

| 4 | 130.25.710 | 844 | 576 | 148 | 808 | 612 | 28 | 18 | M16 | 32 | 4 | 10 | 32 | 300 | |

| 5 | 130.32.800 | 964 | 636 | 182 | 920 | 680 | 36 | 22 | M20 | 40 | 4 | 10 | 40 | 500 | |

| 6 | 130.32.900 | 1064 | 736 | 182 | 1020 | 780 | 36 | 22 | M20 | 40 | 4 | 10 | 40 | 600 | |

| 7 | 130.32.1000 | 1164 | 836 | 182 | 1120 | 880 | 40 | 22 | M20 | 40 | 5 | 10 | 40 | 680 | |

| 8 | 130.32.1120 | 1284 | 956 | 182 | 1240 | 1000 | 40 | 22 | M20 | 40 | 5 | 10 | 40 | 820 | |

| 9 | 130.40.1250 | 1445 | 1055 | 220 | 1393 | 1107 | 45 | 26 | M24 | 48 | 5 | 10 | 50 | 1200 | |

| 10 | 130.40.1400 | 1595 | 1205 | 220 | 1543 | 1257 | 45 | 26 | M24 | 48 | 5 | 10 | 50 | 1300 | |

| 11 | 130.40.1600 | 1795 | 1405 | 220 | 1743 | 1457 | 48 | 26 | M24 | 48 | 6 | 10 | 50 | 1520 | |

| 12 | 130.40.1800 | 1995 | 1605 | 220 | 1943 | 1657 | 48 | 26 | M24 | 48 | 6 | 10 | 50 | 1750 | |

| 13 | 130.45.2000 | 2221 | 1779 | 231 | 2155 | 1845 | 60 | 33 | M30 | 60 | 6 | 12 | 54 | 2400 | |

| 14 | 130.45.2240 | 2461 | 2019 | 231 | 2395 | 2085 | 60 | 33 | M30 | 60 | 6 | 12 | 54 | 2700 | |

| 15 | 130.45.2500 | 2721 | 2279 | 231 | 2655 | 2345 | 72 | 33 | M30 | 60 | 8 | 12 | 54 | 3000 | |

| 16 | 130.45.2800 | 3021 | 2579 | 231 | 2955 | 2645 | 72 | 33 | M30 | 60 | 8 | 12 | 54 | 3400 | |

| 17 | 130.50.3150 | 3432 | 2868 | 270 | 3342 | 2958 | 72 | 45 | M42 | 84 | 8 | 12 | 65 | 5000 | |

| 18 | 130.50.3550 | 3832 | 3268 | 270 | 3742 | 3358 | 72 | 45 | M42 | 84 | 8 | 258 | 65 | 5680 | |

| 19 | 130.50.4000 | 4282 | 3718 | 270 | 4192 | 3808 | 80 | 45 | M42 | 84 | 8 | 258 | 65 | 6470 | |

| 20 | 130.50.4500 | 4782 | 4218 | 270 | 4692 | 4308 | 80 | 45 | M42 | 84 | 8 | 258 | 65 | 7320 | |

THANK YOU FOR YOUR ATTENTION HUAXIN!

If you are interested in this steel product, please fill in this form, we will reply you as soon as possible.