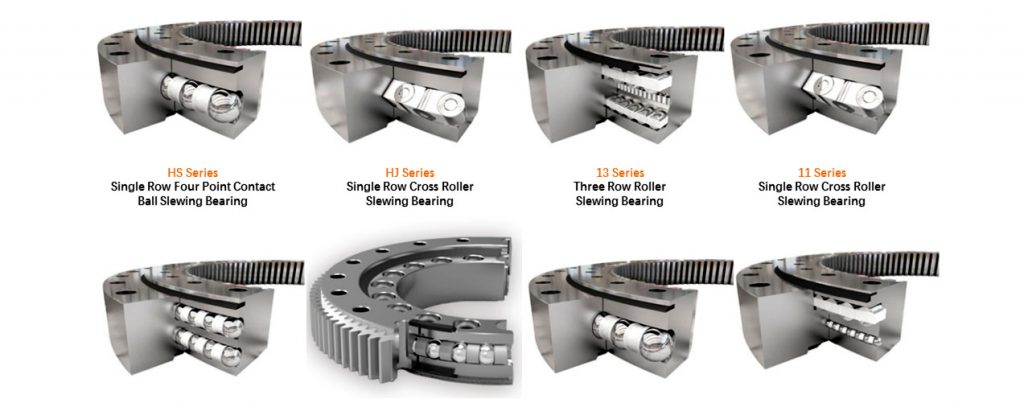

Cross Roller Slewing Bearing

10 Years Of Manufacturing, R&D And Sales

- Characteristic of structure: Single row cross roller slewing bearing is composed of two seat rings

- Performance: Can withstand axial force, radial force and overturning moment

- Features: Used in rotary conveyors, welding operators, light and medium-sized cranes, excavators and other construction machinery

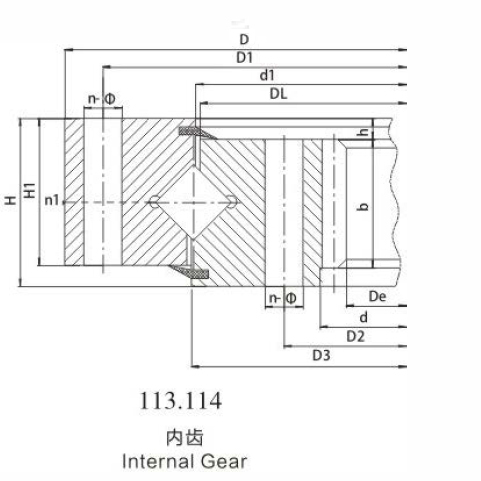

Cross roller slewing system internal gear slewing bearing represent the pinnacle of precision engineering and load-bearing capability in rotational systems. These specialized bearings are meticulously crafted to facilitate smooth and accurate movement, making them indispensable in a wide array of industrial applications. With their internal gear design, they offer seamless integration with gear-driven machinery, providing reliable torque transmission and rotational control.

Core components:

- Cross Roller Elements: The defining feature of cross roller slewing bearings is the arrangement of cylindrical rollers intersecting at right angles between the inner and outer rings. This unique configuration ensures optimal load distribution, high rigidity, and exceptional rotational accuracy.

- Inner Ring: Serving as the primary mounting surface for rotating machinery, the inner ring of a cross roller slewing bearing provides structural support and facilitates precise positioning.

- Internal Gear: In systems requiring torque transmission and rotational control, the inclusion of an internal gear within the slewing bearing assembly is paramount. The internal gear interfaces seamlessly with external gear systems, facilitating precise motion control and efficient power transmission.

- Raceways: Both the inner and outer rings of cross roller slewing bearings feature precision-machined raceways that guide the motion of the roller elements. These raceways are designed to minimize friction, optimize load distribution, and ensure smooth rotational movement.

Applications of Internal Gear Slewing Bearing:

Internal Gear Slewing Bearings find wide-ranging applications across construction, maritime, aerospace, and material handling industries. In the construction sector, they support crane systems, enabling precise load positioning and maneuverability. These bearings facilitate smooth rotation in ship loaders and unloaders within maritime applications, enhancing operational efficiency in port environments. In aerospace systems, Internal Gear skewing bearings contribute to the precise movement of components in aircraft and spacecraft

| No. | Non gear Dùmm | Dimensions | Mounting Dimensions | Structural Dimensions | Weightkg | |||||||||||

| Dmm | dmm | Hmm | DImm | D2mm | n | φmm | dmmm | Lmm | n1mm | D3mm | d1mm | H1mm | hmm | |||

| 1 | 110.25.500 | 602 | 398 | 75 | 566 | 434 | 20 | 18 | M16 | 32 | 4 | 498 | 502 | 65 | 10 | 80 |

| 2 | 110.25.560 | 662 | 458 | 75 | 626 | 494 | 20 | 18 | M16 | 32 | 4 | 558 | 562 | 65 | 10 | 90 |

| 3 | 110.25.630 | 732 | 528 | 75 | 696 | 564 | 24 | 18 | M16 | 32 | 4 | 628 | 632 | 65 | 10 | 100 |

| 4 | 110.25.710 | 812 | 608 | 75 | 776 | 644 | 24 | 18 | M16 | 32 | 4 | 708 | 712 | 65 | 10 | 110 |

| 5 | 110.28.800 | 922 | 678 | 82 | 878 | 722 | 30 | 22 | M20 | 40 | 6 | 798 | 802 | 72 | 10 | 160 |

| 6 | 110.28.900 | 1022 | 778 | 82 | 978 | 822 | 30 | 22 | M20 | 40 | 6 | 898 | 902 | 72 | 10 | 190 |

| 7 | 110.28.1000 | 1122 | 878 | 82 | 1078 | 922 | 36 | 22 | M20 | 40 | 6 | 998 | 1002 | 72 | 10 | 190 |

| 8 | 110.28.1120 | 1242 | 998 | 82 | 1198 | 1042 | 36 | 22 | M20 | 40 | 6 | 1118 | 1122 | 72 | 10 | 230 |

| 9 | 110.32.1250 | 1390 | 1110 | 91 | 1337 | 1163 | 40 | 26 | M24 | 48 | 5 | 1248 | 252 | 81 | 10 | 350 |

| 10 | 110.32.1400 | 1540 | 1260 | 91 | 1487 | 1313 | 40 | 26 | M24 | 48 | 5 | 1398 | 402 | 81 | 10 | 400 |

| 11 | 110.32.1600 | 1740 | 1460 | 91 | 1687 | 1513 | 45 | 26 | M24 | 48 | 5 | 1598 | 1602 | 81 | 10 | 440 |

| 12 | 110.32.1800 | 1940 | 1660 | 91 | 1887 | 1713 | 45 | 26 | M24 | 48 | 5 | 1798 | 1802 | 81 | 10 | 500 |

| 13 | 110.40.2000 | 2178 | 1825 | 112 | 2110 | 1891 | 48 | 33 | M30 | 60 | 8 | 1997 | 2003 | 100 | 12 | 820 |

| 14 | 110.40.2240 | 2418 | 2065 | 112 | 2350 | 2131 | 48 | 33 | M30 | 60 | 8 | 2237 | 2243 | 100 | 12 | 930 |

| 15 | 110.40.2500 | 2678 | 2325 | 112 | 2610 | 2391 | 56 | 33 | M30 | 60 | 8 | 2497 | 2503 | 100 | 12 | 880 |

| 16 | 110.40.2800 | 2978 | 2625 | 112 | 2910 | 2691 | 56 | 33 | M30 | 60 | 8 | 2797 | 2803 | 100 | 12 | 1250 |

| 17 | 110.50.3150 | 3376 | 2922 | 134 | 3286 | 3014 | 56 | 45 | M42 | 84 | 8 | 3147 | 3153 | 122 | 12 | 1990 |

| 18 | 110.50.3550 | 3776 | 3322 | 134 | 3686 | 3414 | 56 | 45 | M42 | 84 | 8 | 3547 | 3553 | 122 | 12 | 2470 |

| 19 | 110.50.4000 | 4226 | 3772 | 134 | 4136 | 3864 | 60 | 45 | M42 | 84 | 10 | 3997 | 4003 | 122 | 12 | 2800 |

| 20 | 110.50.4500 | 4726 | 4272 | 134 | 4636 | 4364 | 60 | 45 | M42 | 84 | 10 | 4497 | 4503 | 122 | 12 | 3100 |

THANK YOU FOR YOUR ATTENTION HUAXIN!

If you are interested in this steel product, please fill in this form, we will reply you as soon as possible.