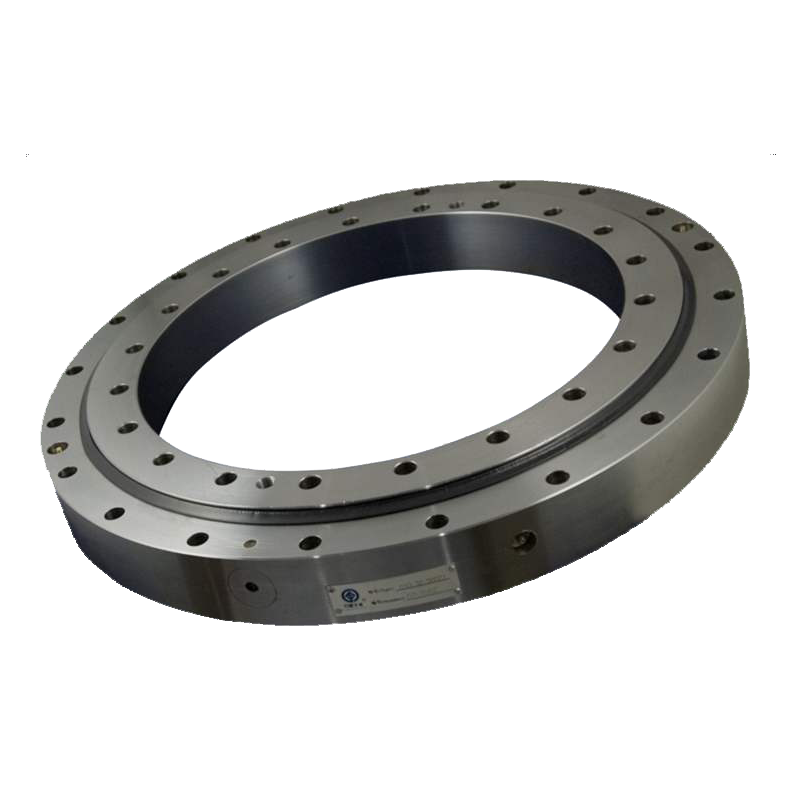

High Precision Slewing Bearing

Double Row Ball Slewing Ring Bearing

HS ball slewing bearing is a high-performance bearings specifically designed to handle a combination of radial, axial, and tilting moment loads. They excel in applications demanding smooth, precise rotation under heavy loads. These bearings are known for their single-row, four-point contact design. This unique configuration utilizes balls between the inner and outer races at four contact points. Design and Construction: HS ball slewing bearing is characterized by a single row of balls sandwiched between a deep groove inner raceway and a deep groove outer raceway. This design feature, known as a four-point contact design, creates a robust contact area between the balls and the races. The balls are typically larger than those found in standard ball bearings, further enhancing the bearing's ability to handle significant loads. Benefits of HS Ball Slewing Bearing Four-Point Contact: Unlike traditional ball bearings with single-point contact, HS bearings utilize a four-point contact design. This is achieved by employing a deep groove gothic arch raceway and a maximum ball complement. The resulting contact between the balls and races distributes loads more evenly, significantly enhancing the bearing's capacity for handling moment loads in all directions. Rectangular Cross-Section: Compared to bearings with round cross-sections, the rectangular design of HS bearings offers several advantages. It allows for a more compact design while maintaining high load capacity. Additionally, the increased rigidity of the rectangular shape minimizes deflection under load, leading to smoother and more precise rotation. Internal Gearing: HS bearings come in two configurations: non-geared and internal-geared. The non-geared option provides a simple design for applications where a separate drive mechanism will be used for rotation. For situations requiring an integrated gear drive, the internal-geared version features teeth machined directly onto the inner or outer diameter of the bearing. This eliminates the need for a separate gear and simplifies the overall system design. Sealing and Lubrication: HS bearings have integral seals to keep contaminants out and lubricant in. They typically use high-quality grease for lubrication and often have grease fittings for easy re-lubrication, ensuring smooth operation and extended bearing life.