The Slewing Bearing Ring is a high-precision component ideal for heavy-duty applications requiring smooth and reliable rotation. It features exceptional load-carrying capacity, handling axial, radial, and moment loads with ease. Its robust construction ensures long-term durability and minimal maintenance, reducing operational costs. The bearing’s design allows for easy integration into various machinery, enhancing performance and efficiency. With advanced sealing technology, it offers excellent protection against contaminants, ensuring optimal functionality in harsh environments. The Slewing Bearing Ring’s versatility makes it perfect for use in cranes, excavators, wind turbines, and other industrial equipment, ensuring consistent and reliable performance.

Components: SLewing Bearing Ring

A slewing bearing ring, also known as a slewing ring bearing or turntable bearing, is a rotational rolling-element bearing that typically supports a heavy but slow-turning or slow-oscillating load, often a horizontal platform such as a conventional crane, a swing yarder, or the wind-facing platform of a horizontal-axis windmill. Here are the main components and features of a slewing bearing ring:

Main Components

- Outer Ring

- The outer ring of the slewing bearing is usually fixed to a stationary part of the machinery. It is designed to support radial, axial, and tilting moment loads.

- Inner Ring

- The inner ring is typically attached to the rotating part of the machinery. Like the outer ring, it supports multiple types of loads.

- Rolling Elements

- These are the balls or rollers placed between the inner and outer rings. They facilitate the rotational movement and help distribute the load evenly. The type of rolling element can vary:

- Ball Bearings: Suitable for lighter loads and higher speeds.

- Roller Bearings: Suitable for heavier loads and slower speeds.

- These are the balls or rollers placed between the inner and outer rings. They facilitate the rotational movement and help distribute the load evenly. The type of rolling element can vary:

- Cage (Retainer)

- The cage holds the rolling elements in place and ensures they are evenly spaced. This helps reduce friction and wear between the rolling elements.

- Seals SLewing Bearing Ring

- Seals are used to prevent the ingress of contaminants such as dirt, dust, and moisture, which could damage the rolling elements and raceways. They also help retain lubrication within the bearing.

- Mounting Holes

- Both the inner and outer rings have mounting holes for bolts or screws, allowing the bearing to be securely attached to the structure it supports.

Features and Specifications

- Load Capacity

- Slewing bearings are designed to handle axial, radial, and tilting moment loads. The load capacity depends on the bearing size, type, and materials used.

- Material

- Typically made from high-quality steel, which provides strength and durability. The rings and rolling elements are often heat-treated to enhance their load-bearing capacity and resistance to wear and fatigue.

- Lubrication

- Proper lubrication is crucial for the smooth operation of slewing bearings. They are often equipped with grease fittings to facilitate regular maintenance.

- Preload

- Some slewing bearings are preloaded to eliminate internal clearance and improve rigidity. Preload helps reduce deflection and increase the bearing’s accuracy and stability.

- Customization

- Slewing bearings can be customized based on the specific requirements of the application, including size, load capacity, and materials.

Applications

Slewing bearing rings are used in a variety of applications, including:

- Cranes and Excavators: To support and rotate the boom or arm.

- Wind Turbines: To allow the nacelle to rotate and face the wind.

- Medical Equipment: Such as CT scanners and surgical tables for precise rotational movement.

- Robotics: In robotic arms and turntables for smooth and accurate positioning.

- Industrial Machinery: For rotating worktables and large machinery components.

Maintenance:SLewing Bearing Ring

Regular maintenance of slewing bearings includes:

- Inspection: Regular checks for wear, corrosion, and proper alignment.

- Lubrication: Periodic greasing to ensure smooth operation and reduce friction.

- Tightening Bolts: Ensuring that mounting bolts remain secure and appropriately torqued.

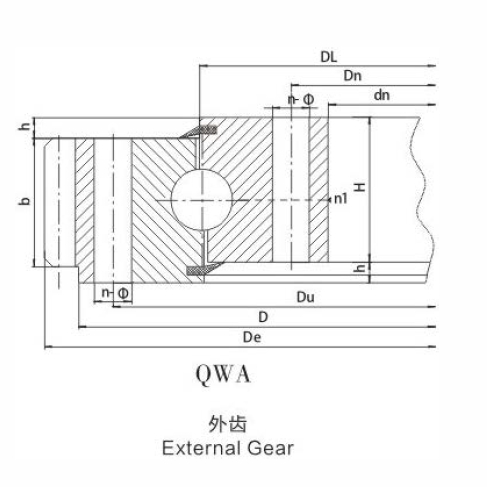

Series Q–External gear

| Model | Dimensions | Mounting Dimensions | Structural Dimensions | Gear Data | |||||||||||||

| ExternalGear | H | Du | Dn | n | A Through Hole A | B/C/DScrew HoleB/C/D | n1 | h | B | m | x=-0.5External Gearx=-0.5 | ||||||

| D | d | φ | d1 | T | De | : | |||||||||||

| mm | nm | mm | mm | kg | |||||||||||||

| 1 | QW,315.20 | 406 | 222 | 60 | 370 | 260 | 10 | 17 | M16 | 24 | 2 | 10 | 40 | 3 | 423 | 140 | 35 |

| QW315.20A | 4 | 428 | 106 | 36 | |||||||||||||

| 2 | QW.355.20 | 446 | 262 | 60 | 410 | 300 | 10 | 17 | M16 | 24 | 2 | 10 | 40 | 3 | 462 | 153 | 40 |

| OIW、355.20A | 4 | 468 | 116 | 41 | |||||||||||||

| 3 | OW.400.20 | 490 | 307 | 60 | 455 | 345 | 12 | 17 | M16 | 24 | 2 | 10 | 40 | 4 | 512 | 127 | 45 |

| OW.400.20.4 | 5 | 520 | 103 | 47 | |||||||||||||

| 4 | QW,450.20 | 540 | 357 | 60 | 505 | 395 | 12 | 17 | M16 | 24 | 2 | 10 | 40 | 4 | 564 | 140 | 51 |

| QW,450.20A | 5 | 570 | 113 | 53 | |||||||||||||

| 5 | QW500.20 | 590 | 407 | 60 | 555 | 445 | 14 | 17 | M16 | 24 | 2 | 10 | 40 | 5 | 615 | 122 | 56 |

| QW.500.20A | 6 | 624 | 103 | 58 | |||||||||||||

| 6 | QW.560.20 | 654 | 464 | 70 | 618 | 502 | 14 | 17 | M16 | 30 | 2 | 10 | 50 | 4 | 680 | 169 | 78 |

| QW.560.20A | 5 | 685 | 136 | 79 | |||||||||||||

| 7 | QW.630.20 | 724 | 534 | 70 | 688 | 572 | 16 | 17 | M16 | 30 | 2 | 10 | 50 | 4 | 748 | 186 | 86 |

| OW.630.20A | 5 | 755 | 150 | 88 | |||||||||||||

| 8 | QW.710.20 | 804 | 614 | 70 | 768 | 652 | 18 | 17 | M16 | 30 | 2 | 10 | 50 | 5 | 835 | 166 | 99 |

| QW.710.20A | 6 | 840 | 139 | 101 | |||||||||||||

| 9 | OW.800.20 | 894 | 704 | 70 | 858 | 742 | 20 | 17 | M16 | 30 | 2 | 10 | 50 | 6 | 930 | 154 | 114 |

| QW.800.20A | 8 | 936 | 116 | 114 | |||||||||||||

| 10 | QW.800.25 | 904 | 692 | 78 | 864 | 736 | 18 | 22 | M20 | 36 | 2 | 10 | 58 | 6 | 942 | 156 | 143 |

| OW.800.25A | 8 | 952 | 118 | 147 | |||||||||||||

| 11 | OW.900.25 | 1004 | 792 | 78 | 964 | 836 | 20 | 22 | M20 | 36 | 2 | 10 | 58 | 8 | 1048 | 130 | 162 |

| OW.900.25A | 10 | 1060 | 105 | 168 | |||||||||||||

| 12 | OW.1000.25 | 1104 | 892 | 78 | 1064 | 936 | 24 | 22 | M20 | 36 | 2 | 10 | 58 | 8 | 1152 | 143 | 182 |

| QW.1000.25A | 10 | 160 | 115 | 185 | |||||||||||||

| 13 | OW.1000.32 | 1120 | 876 | 90 | 1074 | 926 | 24 | 24 | M22 | 40 | 2 | 10 | 70 | 8 | 1160 | 144 | 227 |

| OW1000.32A | 10 | 1170 | 116 | 232 | |||||||||||||

| 14 | OW.1120.32 | 1240 | 996 | 90 | 1194 | 1046 | 28 | 24 | M22 | 40 | 4 | 10 | 70 | 10 | 300 | 129 | 272 |

| QW.1120.32A | 12 | 308 | 108 | 275 | |||||||||||||

| 15 | QW.1250.32 | 1370 | 1126 | 90 | 1324 | 1176 | 32 | 24 | M22 | 40 | 4 | 10 | 70 | 10 | 430 | 142 | 302 |

| QW.1250,32A | 12 | 1440 | 119 | 309 | |||||||||||||

| 16 | QW.1400.32 | 1520 | 1276 | 90 | 1474 | 1326 | 36 | 24 | M22 | 40 | 4 | 10 | 70 | 12 | 1584 | 131 | 337 |

| OW1400.32A | 14 | 1596 | 113 | 347 | |||||||||||||

| 17 | OW.1250.40 | 1390 | 1108 | 102 | 1336 | 1164 | 32 | 26 | M24 | 45 | 4 | 12 | 80 | 10 | 1450 | 144 | 396 |

| QW.1250.40A | 12 | 1452 | 120 | 392 | |||||||||||||

| 18 | OW1400.40 | 1540 | 1258 | 102 | 1486 | 1314 | 36 | 26 | M24 | 45 | 4 | 12 | 80 | 12 | 608 | 133 | 448 |

| QW.1400.40A | 14 | 1610 | 114 | 443 | |||||||||||||

| 19 | QW.1600.40 | 1740 | 1458 | 102 | 1686 | 1514 | 40 | 26 | M24 | 45 | 4 | 12 | 80 | 12 | 1812 | 150 | 528 |

| OW1600.40A | 14 | 820 | 129 | 534 | |||||||||||||

| 20 | QW.1800.40 | 1940 | 1658 | 102 | 1886 | 1714 | 44 | 26 | M24 | 45 | 4 | 12 | 80 | 14 | 2016 | 143 | 583 |

| QW,1800.40A | 16 | 2032 | 126 | 607 | |||||||||||||

| 21 | OW.1600.50 | 762 | 1434 | 124 | 1704 | 1496 | 40 | 30 | M27 | 50 | 4 | 12 | 100 | 12 | 1824 | 151 | 714 |

| OW.1600.50A | 14 | 834 | 130 | 727 | |||||||||||||

| 22 | OW.1800.50 | 1964 | 1634 | 124 | 1904 | 1696 | 44 | 30 | M27 | 50 | 4 | 12 | 100 | 14 | 2044 | 145 | 845 |

| OW.1800.50A | 16 | 2048 | 127 | 843 | |||||||||||||

| 23 | QW.2000,50 | 2162 | 1834 | 124 | 2104 | 1896 | 48 | 30 | M27 | 50 | 6 | 12 | 100 | 16 | 2240 | 139 | 912 |

| QW.2000.50A | 18 | 2250 | 124 | 927 | |||||||||||||

| 24 | QW.2240.50 | 2402 | 2074 | 124 | 2344 | 2136 | 54 | 30 | M27 | 50 | 6 | 12 | 100 | 16 | 2480 | 154 | 1020 |

| QW.2240.50A | 18 | 2502 | 138 | 1078 | |||||||||||||

| 25 | QW.2500.50 | 2662 | 2334 | 124 | 2604 | 2396 | 60 | 30 | M27 | 50 | 6 | 12 | 100 | 18 | 2754 | 152 | 1171 |

| OW.2500.50A | 20 | 276∩ | 7r | ||||||||||||||

| 76 | QW,2500,60 | ||||||||||||||||

THANK YOU FOR YOUR ATTENTION HUAXIN!

If you are interested in this steel product, please fill in this form, we will reply you as soon as possible.