Slewing Ring Crane

10 Years Of Manufacturing, R&D And Sales

- Characteristic of structure: Single row four point contact ball slewing bearing is composed of two seat rings

- Performance: Can withstand axial force, radial force and overturning moment

- Features: Used in rotary conveyors, welding operators, light and medium-sized cranes, excavators and other construction machinery

Slewing rings for crane is critical components designed to support and enable the rotational movement of the crane’s superstructure. These bearings handle substantial axial, radial, and tilting moment loads, ensuring smooth and reliable operation under heavy-duty conditions. Slewing rings are essential for various types of cranes, including mobile cranes, tower cranes, crawler cranes, and marine cranes.

Key Features Slewing Ring Crane:

- High Load Capacity: Engineered to support significant axial, radial, and moment loads, making them ideal for the demanding conditions of crane operations.

- Smooth Rotation: Designed to provide smooth and consistent rotational movement, crucial for precise and safe crane operation.

- Durable Construction: Made from high-quality materials such as alloy steel, with surface hardening treatments to enhance durability and wear resistance.

- Integrated Gear Options: Available with internal or external gears for seamless integration with drive mechanisms, improving operational efficiency.

- Sealing Solutions: Equipped with advanced seals to protect against contaminants like dust, dirt, and moisture, ensuring reliable performance in various environments.

- Robust Design: Designed to withstand harsh operational conditions, including extreme weather and heavy loads.

- Customization: Customizable in terms of size, gear type, and mounting configurations to suit specific crane models and applications.

Applications:

- Mobile Cranes: Used to enable the rotation of the crane’s superstructure, allowing for flexible and efficient lifting operations.

- Tower Cranes: Essential for the rotation of the crane’s jib, facilitating the precise positioning of loads at various heights.

- Crawler Cranes: Employed to enable the rotation of the crane’s upper structure, providing stability and versatility in heavy lifting tasks.

- Marine Cranes: Utilized in ship-mounted and offshore cranes for reliable and stable rotation under challenging marine conditions.

Technical Specifications:

- Load Capacity: Varies depending on the model and size, typically designed to handle multi-ton loads.

- Bearing Type: Options include single-row ball bearings, double-row ball bearings, three-row roller bearings, and cross-roller bearings.

- Material: Generally made from high-grade alloy steel, with surface hardening treatments for enhanced durability.

- Diameter: Customizable to fit specific crane dimensions, with diameters ranging from several hundred millimeters to several meters.

- Gear Type: Available with internal gears, external gears, or without gears based on application requirements.

- Sealing: Advanced sealing options to protect against environmental factors and ensure long-term reliability.

Maintenance and Care: Regular maintenance is crucial to ensure the optimal performance and longevity of slewing rings in cranes. This includes periodic lubrication, inspection for wear and damage, and replacement of seals as needed. Proper installation and alignment are also essential to prevent premature failure and ensure efficient operation.

Conclusion: Slewing rings for crane is indispensable components that enable the smooth and reliable rotation of the crane’s superstructure, supporting heavy loads and ensuring precise operation. Their robust construction, high load capacity, and customizable features make them suitable for a wide range of crane types and applications. Whether used in mobile cranes, tower cranes, or marine cranes, slewing rings provide the durability and performance required for demanding lifting tasks.

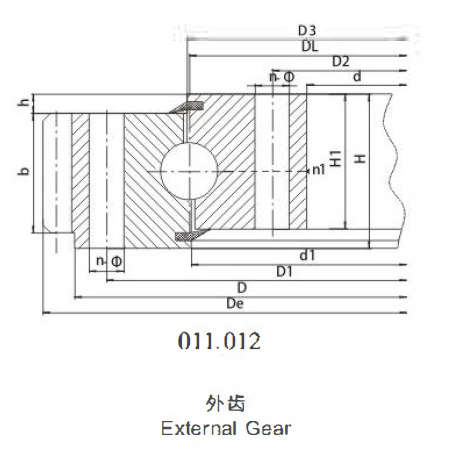

| No. | ExternalgearDLmm | Dimensions | Mounting Dimensions | Structural Dimensions | Gear data | Gearcircumferentialforce | weightkg | ||||||||||||||||

| Dmm | dmm | Hmm | D1mm | D2mm | n | φmim | dmmm | Lmm | n1mm | D3mm | d1mm | H1mm | hmm | bmm | x | Mmm | Demm | Z | Z10*N | T10*N | |||

| 1 | 011.20.200 | 280 | 120 | 60 | 248 | 152 | 12 | 16 | M14 | 28 | 2 | 201 | 199 | 50 | 10 | 40 | 0 | 3 | 300 | 98 | |||

| 2 | 011.20.224 | 304 | 144 | 60 | 272 | 176 | 12 | 16 | M14 | 28 | 2 | 225 | 223 | 50 | 10 | 40 | 0 | 3 | 321 | 105 | |||

| 3 | 011.20.250 | 330 | 170 | 60 | 298 | 202 | 18 | 16 | M14 | 28 | 2 | 251 | 249 | 50 | 10 | 40 | 0 | 4 | 352 | 86 | |||

| 4 | 011.20.280 | 360 | 200 | 60 | 328 | 232 | 18 | 16 | M14 | 28 | 2 | 281 | 279 | 50 | 10 | 40 | 0 | 4 | 384 | 94 | |||

| 5 | 011.25.315 | 408 | 222 | 70 | 372 | 258 | 20 | 18 | M16 | 32 | 2 | 316 | 314 | 60 | 10 | 50 | 0 | 5 | 435 | 85 | 2.9 | 4.4 | |

| 6 | 011.25.355 | 448 | 262 | 70 | 412 | 298 | 20 | 18 | M16 | 32 | 2 | 356 | 354 | 60 | 10 | 50 | 0 | 5 | 475 | 93 | 2.9 | 4.4 | |

| 7 | 011.25.400 | 493 | 307 | 70 | 457 | 343 | 20 | 18 | M16 | 32 | 2 | 401 | 399 | 60 | 10 | 50 | 0 | 6 | 528 | 86 | 3.5 | 5.3 | |

| 8 | 011.25.450 | 543 | 357 | 70 | 507 | 393 | 20 | 18 | M16 | 32 | 2 | 451 | 449 | 60 | 10 | 50 | 0 | 6 | 576 | 94 | 3.5 | 5.3 | |

| 9 | 011.30.500 | 602 | 398 | 80 | 566 | 434 | 20 | 18 | M16 | 32 | 4 | 501 | 498 | 70 | 10 | 60 | 0.5 | 5 | 629 | 123 | 3.7 | 5.2 | 85 |

| 012.30.500 | 6 | 628.8 | 102 | 4.5 | 6.2 | ||||||||||||||||||

| 9H | 011.25.500 | 602 | 398 | 80 | 566 | 434 | 20 | 18 | M16 | 32 | 4 | 501 | 499 | 70 | 10 | 60 | 0.5 | 5 | 629 | 123 | 3.7 | 5.2 | 85 |

| 012.25.500 | 6 | 628.8 | 102 | 4.5 | 6.2 | ||||||||||||||||||

| 10 | 011.30.560 | 662 | 458 | 80 | 626 | 494 | 20 | 18 | M16 | 32 | 4 | 561 | 558 | 70 | 10 | 60 | 0.5 | 5 | 689 | 135 | 3.7 | 5.2 | 95 |

| 012.30.560 | 6 | 688.8 | 112 | 4.5 | 6.2 | ||||||||||||||||||

| 10H | 011.25.560 | 662 | 458 | 80 | 626 | 494 | 20 | 18 | M16 | 32 | 4 | 561 | 559 | 70 | 10 | 60 | 0.5 | 5 | 689 | 135 | 3.7 | 52 | 95 |

| 012.25.560 | 6 | 688.8 | 112 | 4.5 | 6.2 | ||||||||||||||||||

| 11 | 011.30.630 | 732 | 528 | 80 | 696 | 564 | 24 | 18 | M16 | 32 | 4 | 631 | 628 | 70 | 10 | 60 | 0.5 | 6 | 772.8 | 126 | 4.5 | 6.2 | 120 |

| 012.30.630 | 8 | 774.4 | 94 | 6 | 8.3 | ||||||||||||||||||

| 11H | 011.25.630 | 732 | 528 | 80 | 696 | 564 | 24 | 18 | M16 | 32 | 4 | 631 | 629 | 70 | 10 | 60 | 0.5 | 6 | 772.8 | 126 | 4.5 | 6.2 | 110 |

| 012.25.630 | 8 | 774.4 | 94 | 6 | 8.2 | ||||||||||||||||||

| 12 | 011.30.710 | 812 | 608 | 80 | 776 | 644 | 24 | 18 | M16 | 32 | 4 | 711 | 708 | 70 | 10 | 60 | 0.5 | 6 | 850.8 | 139 | 4.5 | 6.2 | 125 |

| 012.30.710 | 8 | 854.4 | 104 | 6 | 8.3 | ||||||||||||||||||

| 12H | 011.25.710 | 812 | 608 | 80 | 776 | 644 | 24 | 18 | M16 | 32 | 4 | 711 | 709 | 70 | 10 | 60 | 0.5 | 6 | 850.8 | 139 | 4.5 | 6.2 | 120 |

| 012.25.710 | S | 854.4 | 104 | 6 | 8.9 | ||||||||||||||||||

| 13 | 011.40.800 | 922 | 678 | 100 | 878 | 722 | 30 | 22 | M20 | 40 | 6 | 801 | 798 | 90 | 10 | 80 | 0.5 | 8 | 966.4 | 118 | S | 11.1 | 220 |

| 012.40.800 | 10 | 968 | 94 | 10 | 14 | ||||||||||||||||||

| 13H | 011.30.800 | 922 | 678 | 100 | 878 | 722 | 30 | 22 | M20 | 40 | 6 | 801 | 798 | 90 | 10 | 80 | 0.5 | 8 | 966.4 | 118 | 8 | 11.1 | 220 |

| 012.30.800 | 10 | 968 | 94 | 10 | 14.1 | ||||||||||||||||||

| 14 | 011.40.900 | 1022 | 778 | 100 | 978 | 822 | 30 | 22 | M20 | 40 | 6 | 901 | 898 | 90 | 10 | 80 | 0.5 | 8 | 1062.4 | 130 | 8 | 11.1 | 240 |

| 012.40.900 | 10 | 1068 | 104 | 10 | 14 | ||||||||||||||||||

| 14H | 011.30.900 | 1022 | 778 | 100 | 978 | 822 | 30 | 22 | M20 | 40 | 6 | 901 | 898 | 90 | 10 | 80 | 0.5 | 8 | 1062.4 | 130 | 8 | 11.1 | 240 |

| 012.30.900 | 10 | 1068 | 104 | 10 | 14 | ||||||||||||||||||

| 15 | 011.40.1000 | 1122 | 878 | 100 | 1078 | 922 | 36 | 22 | M20 | 40 | 6 | 1001 | 998 | 90 | 10 | 80 | 0.5 | 10 | 1188 | 116 | 10 | 14 | 285 |

| 012.40.1000 | 12 | 1185.6 | 96 | 12 | 16.7 | ||||||||||||||||||

| 15H | 011.30.1000 | 1122 | 878 | 100 | 1078 | 922 | 36 | 22 | M20 | 40 | 6 | 1001 | 998 | 90 | 10 | 80 | 0.5 | 10 | 1188 | 116 | 10 | 14 | 270 |

| 012.30.1000 | 12 | 1185.6 | 96 | 12 | 16.7 | ||||||||||||||||||

| 16 | 011.40.1120 | 1242 | 998 | 100 | 1198 | 1042 | 36 | 22 | M20 | 40 | 6 | 1121 | 1118 | 90 | 10 | 80 | 0.5 | 10 | 1298 | 127 | 10 | 14 | 320 |

| 012.40.1120 | 12 | 1305.6 | 106 | 12 | 16.7 | ||||||||||||||||||

THANK YOU FOR YOUR ATTENTION HUAXIN!

If you are interested in this steel product, please fill in this form, we will reply you as soon as possible.