Geared Slewing Ring

10 Years Of Manufacturing, R&D And Sales

- Advantages: high load-bearing capacity, low friction, long service life, providing reliable rotation support for heavy equipment.

- Application: The base of large construction machinery such as excavators, cranes, tower cranes, etc. It can withstand heavy loads and provide a stable rotating platform.

- Features: Made of high-quality carbon steel, it is sturdy and durable; precision design ensures smooth rotation; easy to install and maintain, and has a long service life.

- Specifications: Various sizes and specifications, customized on demand.

Geared slewing rings offer significant advantages in various applications. These rings provide precise and smooth rotational movement, crucial for machinery requiring high accuracy. They are designed for heavy-duty operations, ensuring durability and reliability under extreme loads. The integration of gear teeth allows for efficient power transmission, reducing the need for additional components. This enhances the system’s overall efficiency and performance. Additionally, geared slewing rings are versatile, suitable for diverse industries such as construction, mining, and renewable energy. Their robust construction ensures minimal maintenance, leading to reduced downtime and operational costs, ultimately improving productivity and profitability.

Overview: The geared slewing ring, also known as a slewing bearing or turntable bearing, is a crucial component used in various machinery applications that require rotational movement. These bearings are designed to support axial, radial, and moment loads, providing smooth and precise rotation. They are commonly used in heavy equipment such as cranes, excavators, wind turbines, and rotating platforms.

Key Features:

- High Load Capacity: Geared slewing rings are engineered to handle substantial axial and radial loads, making them ideal for heavy-duty applications.

- Precision Engineering: Manufactured with high precision to ensure smooth and accurate rotational movement.

- Durable Construction: Made from high-quality materials such as hardened steel to withstand harsh operating conditions and extend service life.

- Integrated Gear: Features an integrated gear (internal or external) for easy integration with drive mechanisms, enhancing efficiency and reducing the need for additional components.

- Versatile Designs: Available in various designs, including single-row ball, double-row ball, three-row roller, and cross-roller configurations, to meet different application requirements.

- Sealing Options: Equipped with sealing options to protect the bearing from dust, dirt, and moisture, ensuring reliable performance in challenging environments.

- Customization: Can be customized in terms of size, gear type, and mounting configurations to suit specific application needs.

Applications:

- Construction Machinery: Used in cranes, excavators, and aerial work platforms for rotating the upper structure or attachment.

- Wind Turbines: Essential for the yaw and pitch systems, enabling the adjustment of the turbine blades and direction.

- Material Handling: Employed in rotating conveyors, port machinery, and industrial robots for precise positioning and movement.

- Mining Equipment: Utilized in bucket wheel excavators, stackers, and reclaimers for heavy-load rotation.

- Marine Equipment: Used in ship deck cranes and offshore platforms for reliable and stable rotation in marine environments.

Technical Specifications:

- Load Capacity: Varies depending on the model and size, typically ranging from a few kilonewtons (kN) to several meganewtons (MN).

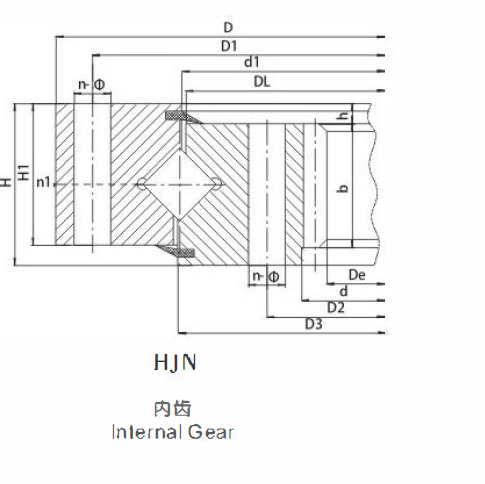

- Gear Type: Available with internal gears, external gears, or without gears based on application requirements.

- Bearing Type: Options include single-row and double-row ball bearings, three-row roller bearings, and cross-roller bearings.

- Material: Generally made from high-grade alloy steel, with surface hardening treatments for enhanced durability.

- Diameter: Customizable to fit specific machinery dimensions, with diameters ranging from a few hundred millimeters to several meters.

Maintenance and Care: To ensure optimal performance and longevity, regular maintenance is essential. This includes periodic lubrication, inspection for wear and damage, and replacement of seals as needed. Proper installation and alignment are also crucial to prevent premature failure and ensure efficient operation.

Conclusion: Geared slewing rings are indispensable components in many industrial applications, providing reliable and precise rotational movement under heavy loads. Their robust construction, high load capacity, and customizable features make them suitable for a wide range of machinery, contributing to improved operational efficiency and performance.

Also check our new series.

| No. | Internal gearDLmm | Dimensions | Mounting Dimensions | Structural Dimensions | Gear data | Gear circumferentialforce | weightkg | |||||||||||||

| Dmm | dmm | Hmm | D1mm | D2mm | n | mm | nlmm | D3mm | d1mm | H1mm | hmm | bmm | x | Mmm | Demm | Z | Quenching | |||

| T10*N | ||||||||||||||||||||

| 1 | HJN.20.625 | 725 | 525 | 80 | 685 | 565 | 18 | 18 | 3 | 627 | 623 | 68 | 12 | 60 | 1.4 | 5 | 498.8 | 101 | 5.2 | 100 |

| HJN.20.625A | 1.15 | 6 | 496.7 | 84 | 6.2 | |||||||||||||||

| 2 | HJN.20.720 | 820 | 620 | 80 | 780 | 660 | 18 | 18 | 3 | 722 | 718 | 68 | 12 | 60 | 1.4 | 6 | 586.6 | 99 | 6.2 | 120 |

| HJN.20.720A | 1 | 8 | 582.3 | 74 | 8.3 | |||||||||||||||

| 3 | HJN.30.820 | 940 | 705 | 95 | 893 | 749 | 24 | 20 | 4 | 822 | 818 | 83 | 12 | 70 | 1.4 | 6 | 664.5 | 112 | 7.2 | 210 |

| HJN.30.820A | 1 | 10 | 658 | 67 | 12.2 | |||||||||||||||

| 4 | HJN.30.880 | 1000 | 760 | 95 | 956 | 800 | 24 | 20 | 4 | 882 | 878 | 83 | 12 | 70 | 1.15 | 8 | 718.2 | 91 | 9.7 | 230 |

| HJN.30.880A | 1 | 10 | 707.9 | 72 | 12.2 | |||||||||||||||

| 5 | HJN.30.1020 | 1170 | 875 | 95 | 1120 | 930 | 24 | 22 | 4 | 1022 | 1018 | 80 | 15 | 70 | 1.4 | 8 | 830.1 | 105 | 9.7 | 300 |

| HJN.30.1020A | 1.15 | 10 | 827.8 | 84 | 12.2 | |||||||||||||||

| 6 | HIN.36.1220 | 1365 | 1075 | 120 | 1310 | 1130 | 36 | 24 | 6 | 1222 | 1218 | 105 | 15 | 90 | 1.4 | 10 | 1027.8 | 104 | 15.7 | 450 |

| HIN.36.1220A | 1 | 12 | 1017.3 | 86 | 18.8 | |||||||||||||||

| 7 | HIN.36.1250 | 1400 | 1090 | 120 | 1350 | 1150 | 36 | 26 | 6 | 1252 | 1248 | 105 | 15 | 90 | -0.35 | 10 | 1037 | 105 | 15.7 | 520 |

| HJN.36.1250A | 1 | 12 | 1028.8 | 87 | 18.8 | |||||||||||||||

| 8 | HJN.36.1435 | 1595 | 1278 | 120 | 1535 | 1335 | 36 | 26 | 6 | 1437 | 1433 | 105 | 15 | 90 | 1.15 | 12 | 1221.2 | 1.3 | 18.8 | 610 |

| HIN.36.1435A | 1 | 14 | 1214.8 | 88 | 21.9 | |||||||||||||||

| 9 | HJN.45.1540 | 1720 | 1360 | 140 | 1660 | 1420 | 42 | 26 | 6 | 1543 | 4537 | 122 | 18 | 110 | 1.4 | 12 | 1293.1 | 109 | 23 | 732 |

| HJN.45.1540A | 1.15 | 14 | 1284.8 | 93 | 26.8 | |||||||||||||||

| 10 | HJN.45.1700 | 1875 | 1525 | 140 | 1815 | 1585 | 42 | 29 | 6 | 1703 | 1697 | 122 | 18 | 110 | 1.15 | 14 | 1452.7 | 105 | 26.8 | 844 |

| HJN.45.1700A | 1.15 | 16 | 1452.3 | 92 | 30.5 | |||||||||||||||

| 11 | HJN.45.1880 | 2100 | 1665 | 160 | 2030 | 1740 | 48 | 32 | 6 | 1883 | 1876 | 140 | 20 | 115 | 1.4 | 14 | 1592.6 | 115 | 27.8 | 1400 |

| HJN.45.1880A | 1.15 | 18 | 1579.9 | 89 | 35.8 | |||||||||||||||

| 12 | HJN.45.2115 | 2325 | 1900 | 160 | 2245 | 1980 | 48 | 32 | 6 | 2118 | 2112 | 140 | 20 | 115 | 1.4 | 16 | 1804.1 | 114 | 31.9 | 1600 |

| HJN.45.2115A | 1.15 | 20 | 1795.4 | 91 | 40 | |||||||||||||||

| 13 | HJN.45.2370 | 2600 | 2146 | 180 | 2520 | 2220 | 48 | 32 | 6 | 2373 | 2367 | 158 | 22 | 130 | 1.4 | 18 | 2065.6 | 116 | 40.7 | 2100 |

| HJN.45.2370A | 1.15 | 22 | 2040.9 | 94 | 49.7 | |||||||||||||||

| 14 | HJN.45.2600 | 2835 | 2365 | 180 | 2750 | 2450 | 54 | 36 | 6 | 2603 | 2597 | 158 | 22 | 130 | 1.4 | 18 | 2263.5 | 127 | 37.6 | 2400 |

| HJN.45.2600A | 1.15 | 22 | 2260.8 | 104 | 45.9 | |||||||||||||||

| 15 | HJN.50.2820 | 3085 | 2555 | 200 | 3000 | 2640 | 54 | 36 | 6 | 2823 | 2817 | 178 | 22 | 150 | 1.4 | 20 | 2455 | 124 | 52.2 | 3400 |

| HJN.50.2820A | 1.15 | 25 | 2444.1 | 99 | 65.3 | |||||||||||||||

| 16 | HJN.50.3120 | 3400 | 2840 | 200 | 3310 | 2930 | 54 | 36 | 6 | 3123 | 3117 | 178 | 22 | 150 | 1.4 | 22 | 2722.5 | 125 | 57.4 | 4000 |

| HJN.50.3120A | 1.4 | 25 | 2719 | 110 | 65.3 | |||||||||||||||

| 17 | HJN.50.3580 | 3920 | 3240 | 240 | 3820 | 3340 | 60 | 40 | 6 | 3583 | 3577 | 218 | 22 | 190 | 1.4 | 22 | 3118.4 | 143 | 72.7 | 6700 |

| HJN.50.3580A | 1.4 | 25 | 3118.8 | 126 | 82.6 | |||||||||||||||

| 18 | HJN.50.4030 | 4370 | 3690 | 240 | 4270 | 3790 | 66 | 40 | 6 | 4033 | 4027 | 218 | 22 | 190 | 1.4 | 22 | 3558.3 | 163 | 53.6 | 7700 |

| HJN.50.4030A | 1.4 | 28 | 3549 | 128 | 68.2 | |||||||||||||||

| 19 | HJN.50.4540 | 4860 | 4210 | 240 | 4760 | 4310 | 72 | 40 | 6 | 4543 | 4537 | 218 | 22 | 190 | 1.4 | 22 | 4042.2 | 185 | 72.1 | 8760 |

| HJN.50.4540A | 1.4 | 30 | 4042.4 | 136 | 99.1 | |||||||||||||||

THANK YOU FOR YOUR ATTENTION HUAXIN!

If you are interested in this steel product, please fill in this form, we will reply you as soon as possible.