Descriptions

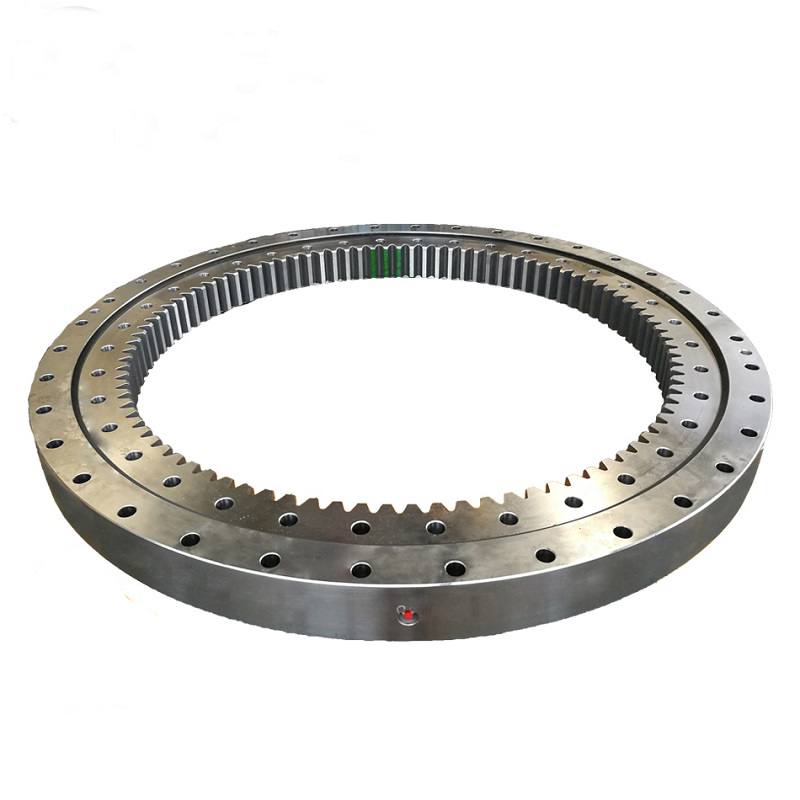

Our Ball Bearing Slewing Rings offer exceptional performance and durability for heavy-duty applications. Available in outer diameters from 120 mm to 2500 mm and in 66 standard variants, these bearings are designed to meet diverse operational needs. They come in both gearless and geared options, ensuring compatibility with various machinery. Key advantages include high load capacity, precise rotational movement, and long service life. The robust construction, combined with advanced sealing, protects against contaminants, while the optional gear teeth provide efficient power transmission. Ideal for cranes, wind turbines, and industrial equipment.

Features

Ball bearing slewing rings, also known as ball slewing bearings or turntable bearings, are rotational rolling-element bearings that primarily use balls as the rolling elements. They are designed to accommodate axial, radial, and moment loads simultaneously. Here is an overview of the key components, features, applications, and maintenance considerations for ball bearing slewing rings:

Key Components

- Outer Ring

- The stationary part of the bearing that is often fixed to the machine frame or structure.

- Inner Ring

- The rotating part of the bearing that attaches to the moving component of the machine.

- Balls

- The rolling elements that facilitate the rotational movement between the inner and outer rings. The balls are typically made from high-strength steel to withstand heavy loads and provide durability.

- Cage (Separator)

- The component that holds the balls in place and ensures they are evenly spaced. The cage reduces friction and prevents the balls from colliding with each other.

- Seals

- Seals protect the bearing from contaminants such as dust, dirt, and moisture, and help retain lubrication within the bearing.

- Mounting Holes

- Both the inner and outer rings have holes for bolts or screws to secure the bearing to the structure and the rotating component.

Features and Specifications

- Load Capacity

- Ball bearing slewing rings can handle a combination of axial, radial, and tilting moment loads. The capacity varies depending on the bearing size, ball diameter, and material.

- Material

- The rings are usually made of high-quality steel, often heat-treated to enhance strength and resistance to wear. The balls are also typically made of high-strength steel.

- Lubrication

- Proper lubrication is essential for smooth operation and long life. These bearings are often equipped with grease fittings to facilitate regular lubrication maintenance.

- Preload

- Some slewing rings are designed with preload to eliminate internal clearance and improve stiffness and precision.

- Customization

- Bearings can be customized in terms of size, load capacity, material, and specific design features to meet the requirements of different applications.

Applications

Ball bearing slewing rings are used in various industries and applications, including:

- Cranes and Excavators

- For the rotational movement of the boom or upper structure.

- Wind Turbines

- To allow the nacelle and blades to rotate and face the wind direction.

- Medical Equipment

- In CT scanners, surgical tables, and other devices requiring precise rotational movement.

- Robotics

- For the rotation of robotic arms and turntables.

- Industrial Machinery

- In rotating worktables, assembly lines, and other heavy machinery.

- Aerospace

- For satellite dish positioning and other applications requiring precise movement.

Maintenance

Proper maintenance of ball bearing slewing rings includes:

- Regular Inspection

- Check for signs of wear, corrosion, and proper alignment. Look for unusual noises or vibrations during operation.

- Lubrication

- Regularly lubricate the bearing to reduce friction and wear. Follow the manufacturer’s recommendations for lubrication intervals and types of grease.

- Tightening Bolts

- Ensure that the mounting bolts are secure and properly torqued to prevent loosening and misalignment.

- Cleaning

- Keep the bearing and surrounding area clean to prevent contaminants from entering and causing damage.

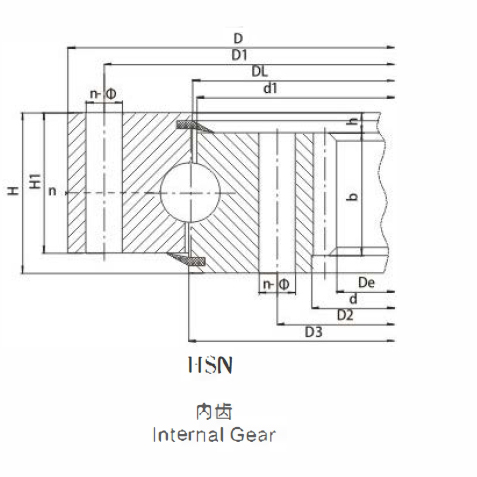

| No. | Internal gearDLmm | Dimensions | Mounting Dimensions | Structural Dimensions | Gear data | earcircumferentialforce | weightkg | |||||||||||||

| Dmm | dmm | Hmm | D1mm | D2mm | n | φmm | nlmm | D3mm | d1mm | H1mm | hmm | bmm | X | Mmm | Demm | Z | T10’N | |||

| 1 | HSN.25.625 | 725 | 525 | 80 | 685 | 565 | 18 | 18 | 3 | 626 | 624 | 68 | 12 | 60 | 1.4 | 5 | 498.8 | 101 | 5.2 | 100 |

| HSN.25.625A | 1.15 | 6 | 496.7 | 84 | 6.2 | |||||||||||||||

| 2 | HSN.25.720 | 820 | 620 | 80 | 780 | 660 | 18 | 18 | 3 | 721 | 719 | 68 | 12 | 60 | 1.4 | 6 | 586.6 | 99 | 6.2 | 120 |

| HSN.25.720A | 1 | 8 | 582.3 | 74 | 8.3 | |||||||||||||||

| 3 | HSN.30.820 | 940 | 705 | 95 | 893 | 749 | 24 | 20 | 4 | 821 | 818 | 83 | 12 | 70 | 1.4 | 6 | 664.5 | 112 | 7.2 | 210 |

| HSN.30.820A | 1 | 10 | 658 | 67 | 12.2 | |||||||||||||||

| 4 | HSN.30.880 | 1000 | 760 | 95 | 956 | 800 | 24 | 20 | 4 | 881 | 878 | 83 | 12 | 70 | 1.15 | 8 | 718.2 | 91 | 9.7 | 230 |

| HSN.30.880A | 1 | 10 | 707.9 | 72 | 12.2 | |||||||||||||||

| 5 | HSN.30.1020 | 1170 | 875 | 95 | 1120 | 930 | 24 | 22 | 4 | 1021 | 1018 | 80 | 15 | 70 | 1.4 | 8 | 830.1 | 105 | 9.7 | 300 |

| HSN.30.1020A | 1.15 | 10 | 827.8 | 84 | 12.2 | |||||||||||||||

| 6 | HSN.30.1220 | 1365 | 1075 | 120 | 1310 | 1130 | 36 | 24 | 6 | 1221 | 1218 | 105 | 15 | 90 | 1.4 | 10 | 1027.8 | 104 | 15.7 | 450 |

| HSN.30.1220A | 1 | 12 | 1017.3 | 86 | 18.8 | |||||||||||||||

| 7 | HSN.35.1250 | 1400 | 1090 | 120 | 1350 | 1150 | 36 | 26 | 6 | 1251 | 1248 | 105 | 15 | 90 | -0.35 | 10 | 1037 | 105 | 15.7 | 520 |

| HSN.35.1250A | 1 | 12 | 1028.8 | 87 | 18.8 | |||||||||||||||

| 8 | HSN.35.1435 | 1595 | 1278 | 120 | 1535 | 1335 | 36 | 26 | 6 | 1436 | 1433 | 105 | 15 | 90 | 1.15 | 12 | 1221.2 | 103 | 18.8 | 610 |

| HSN.35.1435A | 1 | 14 | 1214.8 | 88 | 21.9 | |||||||||||||||

| 9 | HSN.35.1540 | 1720 | 1360 | 140 | 1660 | 1420 | 42 | 26 | 6 | 1541 | 1538 | 122 | 18 | 110 | 1.4 | 12 | 1293.1 | 109 | 23 | 732 |

| HSN.35.1540A | 1.15 | 14 | 1284.8 | 93 | 26.8 | |||||||||||||||

| 10 | HSN.35.1700 | 1875 | 1525 | 140 | 1815 | 1585 | 42 | 29 | 6 | 1701 | 1698 | 122 | 18 | 110 | 1.15 | 14 | 1452.7 | 105 | 26.8 | 844 |

| HSN.35.1700A | 1.15 | 16 | 1452.3 | 92 | 30.5 | |||||||||||||||

| 11 | HSN.40.1880 | 2100 | 1665 | 160 | 2030 | 1740 | 48 | 32 | 6 | 1881 | 1878 | 140 | 20 | 115 | 1.4 | 14 | 1592.6 | 115 | 27.8 | 1400 |

| HSN.40.1880A | 1.15 | 18 | 1579.9 | 89 | 35.8 | |||||||||||||||

| 12 | HSN.40.2115 | 2325 | 1900 | 160 | 2245 | 1980 | 48 | 32 | 6 | 2116 | 2113 | 140 | 20 | 115 | 1.4 | 16 | 1804.1 | 114 | 31.9 | 1600 |

| HSN.40.2115A | 1.15 | 20 | 1795.4 | 91 | 40 | |||||||||||||||

| 13 | HSN.40.2370 | 2600 | 2146 | 180 | 2520 | 2220 | 48 | 32 | 6 | 2371 | 2368 | 158 | 22 | 130 | 1.4 | 18 | 2065.6 | 116 | 40.7 | 2100 |

| HSN.40.2370A | 1.15 | 22 | 2040.9 | 94 | 49.7 | |||||||||||||||

| 14 | HSN.40.2600 | 2835 | 2365 | 180 | 2750 | 2450 | 54 | 36 | 6 | 2601 | 2598 | 158 | 22 | 130 | 1.4 | 18 | 2263.5 | 127 | 37.6 | 2400 |

| HSN.40.2600A | 1.15 | 22 | 2260.8 | 104 | 45.9 | |||||||||||||||

| 15 | HSN.50.2820 | 3085 | 2555 | 200 | 3000 | 2640 | 54 | 36 | 6 | 2822 | 2818 | 178 | 22 | 150 | 1.4 | 20 | 2455 | 124 | 52.2 | 3400 |

| HSN.50.2820A | 1.15 | 25 | 2444.1 | 99 | 65.3 | |||||||||||||||

| 16 | HSN.50.3120 | 3400 | 2840 | 200 | 3310 | 2930 | 54 | 36 | 6 | 3122 | 3118 | 178 | 22 | 150 | 1.4 | 22 | 2722.5 | 125 | 57.4 | 4000 |

| HSN.50.3120A | 1.4 | 25 | 2719 | 110 | 65.3 | |||||||||||||||

| 17 | HSN.50.3580 | 3920 | 3240 | 240 | 3820 | 3340 | 60 | 40 | 6 | 3582 | 3578 | 218 | 22 | 190 | 1.4 | 22 | 3118.4 | 143 | 72.7 | 6700 |

| HSN.50.3580A | 1.4 | 25 | 3118.8 | 126 | 82.6 | |||||||||||||||

| 18 | HSN.50.4030 | 4370 | 3690 | 240 | 4270 | 3790 | 66 | 40 | 6 | 4032 | 4028 | 218 | 22 | 190 | 1.4 | 22 | 3558.3 | 163 | 53.6 | 7700 |

| HSN.50.4030A | 1.4 | 28 | 3549 | 128 | 68.2 | |||||||||||||||

| 19 | HSN.50.4540 | 4860 | 4210 | 240 | 4760 | 4310 | 72 | 40 | 6 | 4542 | 4538 | 218 | 22 | 190 | 1.4 | 22 | 4042.2 | 185 | 72.1 | 8760 |

| HSN.50.4540A | 1.4 | 30 | 4042.4 | 136 | 99.1 | |||||||||||||||

THANK YOU FOR YOUR ATTENTION HUAXIN!

If you are interested in this steel product, please fill in this form, we will reply you as soon as possible.