Slewing Ring Bearings

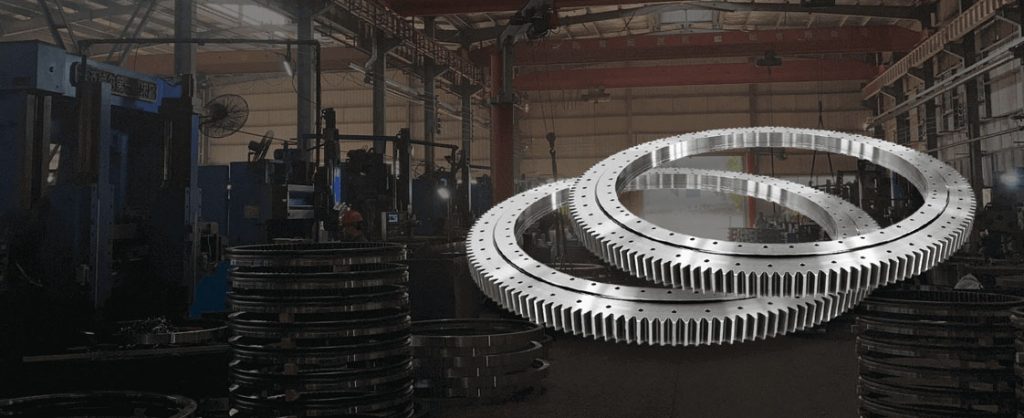

10 Years Of Manufacturing, R&D And Sales

- OEM/ODM: Slewing Ring Bearings are available in a variety of models and can be customized according to customer needs.

- Quality: The products are manufactured in strict accordance with international standards and undergo rigorous quality testing. Advanced production technology and testing methods are used to ensure stable and reliable product quality.

- Application: It is used in engineering machinery, mining equipment, marine equipment, wind power equipment and other fields, and is a key accessory for heavy-duty equipment.

- Features: Made of high-quality steel, it has strong load-bearing capacity and long service life. The inner and outer rings are designed with rolling elements to achieve smooth and low-noise rotation.

Our Slewing Ring Bearings are designed for optimal performance in heavy-duty applications. With diameters ranging from 120 mm to 7000 mm, they come in 66 standard variants, available in both gearless and geared options. These bearings offer high load capacity, precise rotation, and exceptional durability. Advanced sealing protects against contaminants, ensuring long service life. Ideal for cranes, wind turbines, and industrial equipment, our slewing ring bearings deliver reliable and efficient performance in demanding environments. Choose our bearings for superior quality and dependability in your critical applications.

Core Components:

Slewing ring bearings, also known as slewing bearings or turntable bearings, are versatile and robust components used to support heavy loads and enable rotational movement in machinery. Here’s an in-depth look at slewing ring bearings, including their types, components, features, applications, and maintenance considerations:

Types of Slewing Ring Bearings

- Single-row Ball Slewing Bearings

- Contains a single row of balls. Suitable for applications with lower load capacity requirements.

- Double-row Ball Slewing Bearings

- Contains two rows of balls. Provides higher load capacity and better distribution of loads.

- Three-row Roller Slewing Bearings

- Contains three rows of rollers. Offers the highest load capacity and is suitable for heavy-duty applications.

- Crossed Roller Slewing Bearings

- Contains rollers arranged in a crisscross pattern. Provides high rigidity and accuracy, ideal for applications requiring precise movement.

- Single-row Four-point Contact Ball Slewing Bearings

- Features a single row of balls with a four-point contact between the balls and raceways. Suitable for combined axial, radial, and tilting moment loads.

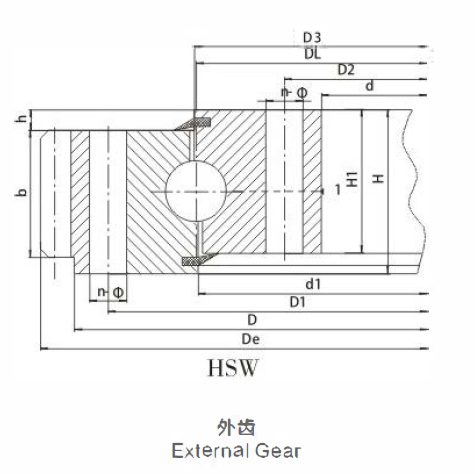

Components of Slewing Ring Bearings

- Inner and Outer Rings

- The main structural components. One ring is usually fixed while the other rotates. Both rings have mounting holes for bolts.

- Rolling Elements

- Balls or rollers placed between the inner and outer rings to facilitate smooth rotational movement.

- Cage (Separator)

- Maintains even spacing of the rolling elements and prevents them from colliding.

- Seals

- Protect the bearing from contaminants and retain lubrication inside the bearing.

- Grease Fittings

- Allow for easy lubrication of the bearing during maintenance.

Features and Specifications

- Load Capacity

- Designed to handle axial, radial, and tilting moment loads. Capacity varies based on the type, size, and design of the bearing.

- Material

- Typically made from high-strength steel, often heat-treated for enhanced durability and load-bearing capacity.

- Lubrication

- Essential for smooth operation. Bearings are equipped with grease fittings for regular lubrication.

- Preload

- Some bearings are preloaded to eliminate internal clearance, improving stiffness and precision.

- Customization

- Can be tailored to specific application requirements, including size, load capacity, and material.

Applications

Slewing ring bearings are used in various industries and applications, including:

- Cranes and Excavators

- For rotational movement of the boom or upper structure.

- Wind Turbines

- To allow the nacelle and blades to rotate and face the wind direction.

- Medical Equipment

- In devices like CT scanners and surgical tables requiring precise rotational movement.

- Robotics

- For rotation of robotic arms and turntables.

- Industrial Machinery

- In rotating worktables, assembly lines, and heavy machinery.

- Aerospace

- For satellite dish positioning and other precision applications.

- Marine Equipment

- For rotating parts of ships and offshore equipment.

Maintenance

Proper maintenance of slewing ring bearings includes:

- Regular Inspection

- Check for wear, corrosion, and proper alignment. Listen for unusual noises or vibrations during operation.

- Lubrication

- Regularly lubricate to reduce friction and wear. Follow manufacturer recommendations for lubrication intervals and types of grease.

- Bolt Tightening

- Ensure mounting bolts are secure and properly torqued to prevent loosening and misalignment.

- Cleaning

- Keep the bearing and surrounding area clean to prevent contamination.

- Replacement

- Monitor the bearing’s condition and replace it when it shows signs of significant wear or damage.

| No. | ExternalBEmm | Dimensions | Mounting Dimensions | Structural Dimensions | Gear data | earcircumferentialforce | weightkg | |||||||||||||

| Dmm | dmm | Hmm | D1mm | D2mm | n | φmm | n1mm | D3mm | d1mm | H1mm | hmm | bmm | x | Mmm | Demm | Z | T10*N | |||

| 1 | HSW.25.625 | 725 | 525 | 80 | 685 | 565 | 18 | 18 | 3 | 626 | 624 | 68 | 12 | 60 | 1.4 | 5 | 751.9 | 146 | 5.2 | 100 |

| HSW.25.625A | 1.15 | 6 | 755.5 | 122 | 6.2 | |||||||||||||||

| 2 | HSW.25.720 | 820 | 620 | 80 | 780 | 660 | 18 | 18 | 3 | 721 | 719 | 68 | 12 | 60 | 1.4 | 6 | 860.3 | 139 | 6.2 | 130 |

| HSW.25.720A | 1 | 8 | 861.1 | 104 | 8.3 | |||||||||||||||

| 3 | HSW.30.820 | 940 | 705 | 95 | 893 | 749 | 24 | 20 | 4 | 821 | 818 | 83 | 12 | 70 | 1.4 | 6 | 980.6 | 159 | 7.2 | 210 |

| HSW.30.820A | 1 | 10 | 986.2 | 95 | 12.2 | |||||||||||||||

| 4 | HSW.30.880 | 1000 | 760 | 95 | 956 | 800 | 24 | 20 | 4 | 881 | 878 | 83 | 12 | 70 | 1.15 | 8 | 1047.5 | 127 | 9.7 | 230 |

| HSW.30.880A | 1 | 10 | 1046.3 | 101 | 12.2 | |||||||||||||||

| 5 | HSW.30.1020 | 1170 | 875 | 95 | 1120 | 930 | 24 | 22 | 4 | 1021 | 1018 | 80 | 15 | 70 | 1.4 | 8 | 1219.3 | 148 | 9.7 | 300 |

| HSW.30.1020A | 1.15 | 10 | 1219.2 | 118 | 12.2 | |||||||||||||||

| 6 | HSW.30.1220 | 1365 | 1075 | 120 | 1310 | 1130 | 36 | 24 | 6 | 1221 | 1218 | 105 | 15 | 90 | 1.4 | 10 | 1424.9 | 138 | 15.7 | 450 |

| HSW.30.1220A | 1 | 12 | 1435.9 | 116 | 18.8 | |||||||||||||||

| 7 | HSW.35.1250 | 1400 | 1090 | 120 | 1350 | 1150 | 36 | 26 | 6 | 1251 | 1248 | 105 | 15 | 90 | -0.35 | 10 | 1443 | 143 | 15.7 | 520 |

| HSW.35.1250A | 1 | 12 | 1449.6 | 117 | 18.8 | |||||||||||||||

| 8 | HSW.35.1435 | 1595 | 1278 | 120 | 1535 | 1335 | 36 | 26 | 6 | 1436 | 1433 | 105 | 15 | 90 | 1.15 | 12 | 1655.5 | 134 | 18.8 | 640 |

| HSW.35.1435A | 1 | 14 | 1661.2 | 115 | 21.9 | |||||||||||||||

| 9 | HSW.35.1540 | 1720 | 1360 | 140 | 1660 | 1420 | 42 | 26 | 6 | 1541 | 1538 | 122 | 18 | 110 | 1.4 | 12 | 1780.8 | 144 | 23 | 732 |

| HSW.35.1540A | 1.15 | 14 | 1791.1 | 124 | 26.8 | |||||||||||||||

| 10 | HSW.35.1700 | 1875 | 1525 | 140 | 1815 | 1585 | 42 | 29 | 6 | 1701 | 1698 | 122 | 18 | 110 | 1.15 | 14 | 1945.4 | 135 | 26.8 | 844 |

| HSW.35.1700A | 1.15 | 16 | 1950.8 | 118 | 30.5 | |||||||||||||||

| 11 | HSW.40.1880 | 2100 | 1665 | 160 | 2030 | 1740 | 48 | 32 | 6 | 1881 | 1878 | 140 | 20 | 115 | 1.4 | 14 | 2189.8 | 152 | 27.8 | 1400 |

| HSW.40.1880A | 1.15 | 18 | 2194.6 | 118 | 35.8 | |||||||||||||||

| 12 | HSW.40.2115 | 2325 | 1900 | 160 | 2245 | 1980 | 48 | 32 | 6 | 2116 | 2113 | 140 | 20 | 115 | 1.4 | 16 | 2406.5 | 146 | 31.9 | 1600 |

| HSW.40.2115A | 1.15 | 20 | 2418.4 | 117 | 40 | |||||||||||||||

| 13 | HSW.40.2370 | 2600 | 2146 | 180 | 2520 | 2220 | 48 | 32 | 6 | 2371 | 2368 | 158 | 22 | 130 | 1.4 | 18 | 2707.3 | 146 | 40.7 | 2100 |

| HSW.40.2370A | 1.15 | 22 | 2704.4 | 119 | 49.7 | |||||||||||||||

| 14 | HSW.40.2600 | 2835 | 2365 | 180 | 2750 | 2450 | 54 | 36 | 6 | 2601 | 2598 | 158 | 22 | 130 | 1.4 | 18 | 2941.7 | 159 | 37.6 | 2400 |

| HSW.40.2600A | 1.15 | 22 | 2946.9 | 130 | 45.9 | |||||||||||||||

| 15 | HSW.50.2820 | 3085 | 2555 | 200 | 3000 | 2640 | 54 | 36 | 6 | 2822 | 2818 | 178 | 22 | 150 | 1.4 | 20 | 3188.4 | 155 | 52.2 | 3400 |

| HSW.50.2820A | 1.15 | 25 | 3198.4 | 124 | 65.3 | |||||||||||||||

| 16 | HSW.50.3120 | 3400 | 2840 | 200 | 3310 | 2930 | 54 | 36 | 6 | 3122 | 3118 | 178 | 22 | 150 | 1.4 | 22 | 3507.2 | 155 | 57.4 | 4000 |

| HSW.50.3120A | 1.4 | 25 | 3509.6 | 136 | 65.3 | |||||||||||||||

| 17 | HSW.50.3580 | 3920 | 3240 | 240 | 3820 | 3340 | 60 | 40 | 6 | 3582 | 3578 | 218 | 22 | 190 | 1.4 | 22 | 4036.1 | 179 | 72.7 | 6700 |

| HSW.50.3580A | 1.4 | 25 | 4035.6 | 157 | 82.6 | |||||||||||||||

| 18 | HSW.50.4030 | 4370 | 3690 | 240 | 4270 | 3790 | 66 | 40 | 6 | 4032 | 4028 | 218 | 22 | 190 | 1.4 | 22 | 4520.6 | 201 | 53.6 | 7700 |

| HSW.50.4030A | 1.4 | 28 | 4522.4 | 157 | 68.2 | |||||||||||||||

THANK YOU FOR YOUR ATTENTION HUAXIN!

If you are interested in this steel product, please fill in this form, we will reply you as soon as possible.